Guide To Sanding & Polishing For Jewellery Making

A good quality finish creates a professional, high value and irresistible piece of jewellery that really stands out from the crowd - but how do you get there?

On this page, we talk you through the importance of cleaning your piece of jewellery and preparing it for polishing, our top tools for hand polishing and how to use a power tool to create a high shine. Not only that, we tell you how you can take your piece to the next level of shiny!

Polishing is such an important part of jewellery making and achieving a great finish really can elevate your work to the next level. The art of polishing is very involved with many, many facets and techniques – traditionally, polishing apprenticeships could last as long as three to five years. Excellent results can be achieved by polishing with machinery but with a little patience and the right tools, hand polishing can also provide a superb finish.

Over the years we have found, as with all jewellery making, that polishing is very much a personal thing with no clear best method. Some of you find it therapeutic and satisfying; some of you hate it (in fact, quite a few of you do) but the fact is that it is a necessity so we decided that by compiling our expertise and yours, we may be able to offer a little help.

Below will help you understand the methods and tools available, you can choose the ones which suit you and your project the best - providing a good basic knowledge for you to develop with practice and through your own experimentation.

You can buy all the sanding, cleaning and polishing supplies you need online with Kernowcraft.

The Importance Of Preparation

The first rule of polishing is to prepare your surface well and take your time. Any deep marks, scratches and fire stain may surface during the polishing process which is frustrating, so it's important to get this part right.

Taking extra time and care with your technique can help you save valuable time at the polishing stage. This means making solder joins neat and taking extra care when setting stones - these little things can help cut down on the need for filing and sanding, but of course there will always be a certain amount to do.

Stage 1: Filing

Filing is an important part of the jewellery making progress. Needle files are used to shape and finish your pieces, removing excess metal and solder to tidy up your design.

Needle files are small files, perfect to get into small, hard to reach places. They come in a range of shapes and are often sold in a pack with a set of different shapes, so you can pick and choose the right file for your needs. With practice, you'll soon understand what file is needed for a particular job.

Read our advice page: how to use needle files for jewellery making

Stage 2: Sanding

The next stage for ensuring your jewellery is on the right path for a good finish, is to ensure you don't forget to sand your piece. The secret to a really high shine is all in the pre-polish. The more time and effort you put into this stage the better the results will be.

After construction, your design has been through a lot - fire scale, pickle residue, large scratches and the dreaded fire stain. The following products will help you to remove these and make the polishing stage much easier and more effective.

Take a look at a few options available below.

Wet & Dry Sanding Sheets

We recommend using graded wet and dry sanding sheets to further smooth the surface to be polished and to eliminate any marks you have made with needle files - as well as sanding away any stubborn fire stain.

We sell 3 grades of wet and dry sanding sheets - for best results, work up through the grades from coarse to fine:

400 grit (coarse)

600 grit (medium)

1200 grit (fine)

These excellent quality sanding sheets have been especially developed for use with metals and they are accurately graded with ultra-fine precision to ensure that you get the very best results. The grades we sell have been carefully selected to follow on nicely from the preparation work you did with needle files.

The sheets are made from flexible paper so, although they can be used as they are, you may find it easier to wrap a small piece of a sanding sheet around a block of wood or similar - providing a hard backing for quicker sanding results, as you can apply more pressure as well as prolonging the life of you paper as it wears away less this way.

Or Sanding & Polishing Sticks

Another alternative to wet and dry sanding sheets it to use our sanding and polishing sticks, consisting of sanding and polishing paper in a variety of grades from 3 (coarsest) to 5/0 (finest) already secured to flat pieces of wood.

The down side to these sticks is that you may not be able to get into those tiny nooks and crannies which would be easier with wet and dry sanding sheets as they can be folded and cut into useful shapes.

Which ever you use, start with the coarse grade and work all around your piece until every surface is sanded and smooth - work through all the grades from coarse to fine in the same way.

Try to work all over the piece and move the sanding material and your piece as you sand to avoid any flattened areas. Changing the direction in which you sand between grades also helps to show any marks which could cause issues later on.

Don't be tempted to leave any stages out until you have a good feel for this as it may lead to more work later on.

Take A Critical View

Now is the time to take a really critical view of your piece and make sure that there are no deep marks or scratches. The whole piece will now have a satin appearance and it may look different as you look at the piece from different directions – this is fine but any obvious marks left at this stage are very likely to show more after the piece is polished. If you are at all in doubt, repeat the process again as this is very likely to save you time later on. With a little practice you will soon learn what your piece should look like at this stage.

Zoom In With A Headband Magnifier

A headband magnifier can be a very useful tool to have at this stage as scratches which may not be visible to the naked eye can be much more obvious with magnification. It's great for all types of jewellery making as well as other crafts which include fiddly jobs.

The four magnifying lenses range from 1.2x to 3.5x and slot in and out with ease according to your needs. It has an LED light which can be switched off if it is not needed, the band is fully adjustable for different head sizes and the whole magnifying part can be swung up and out of the way. These can also be worn with prescription glasses.

Sand & Polish With Silicon Carbide Polishers

If you find the process of sanding and polishing laborious and you are looking for a quicker, easier method, these clever silicon carbide polishing points and wheels may be for you. They provide a fast, neat and effective way to finish metals and on most projects they can completely eliminate the need for sanding and greatly reduce the need for filing too.

They are designed for use at high speeds in a hobby or pendant drill (such as our Dremel Multi Tool with the addition of a multi chuck which allows you to fit drill bits and accessories with shanks as small as 0.4mm). They are made from flexible silicon material impregnated with fast cutting carbide abrasives. We sell them in three different shapes: cylinder - useful for polishing flat surfaces and the inside of rings, wheel - useful for polishing up against bezels and decoration and knife edge wheel - useful for polishing in grooves and up against detailing. Mandrels are required for fitting these in your drill (one type for wheels and one for cylinders). All the shapes come in four different colour coded grades;

- Coarse (white) – for grinding away excess metal and pre-polishing

- Medium (black) – for smoothing and refining edges and surfaces

- Fine (blue) – for high sheen polishing

- Extra fine (pink) – for ultra-high sheen polishing

As with all graded sanding and polishing products, we always recommend that you work down through all the grades starting with coarse and ending with extra fine for the best results. The coarser grades (white and black) provide a fast way to grind away excess metal where filing and sanding is tricky or too time consuming as well as providing a very consistent 'pre-polish' finish and then the finer ones (blue and pink) polish the metal and produce a high sheen almost as good as rouge. Whether used as a stand-alone polishing solution or in conjunction with polishing mops and compounds, once people start using these they often wonder why they never tried them before!

Dremel Multi Tool

If you are serious about making jewellery this is one tool you simply can’t do without! As well as being invaluable for high speed polishing, this high quality, compact tool enables you to carry out detailed sanding, carving, engraving, cutting, grinding and cleaning so it can really enhance your jewellery making hobby.

We offer a wide range of accessories that fit the Dremel for more detailed jewellery use including silicon polishers in various shapes, polishing mops as well as a wide variety of stone setting burrs.

We always advise customers to get the multi chuck as well which allows you to quickly and easily change accessories without the need for separate collets.

Stage 3: Polishing

A well polished, good finish can be achieved either by hand or with a rotatory tool such as a Dremel Multi Tool. Using a power tool will speed things up and make things a little easier however, doing things by hand can give you more control, precision and convenience. Often a combination of the two is best!

Hand Polishing With Polishing Papers

If you're a jewellery making beginner or you simply prefer working by hand, our polishing papers are a great choice to achieve a high sheen and getting into hard to reach places. These polishing papers are effective on metal clays as the pure silver is very receptive to gentle polishing methods but very good results can be achieved on harder metals such as sterling silver too.

After you have filed and sanded using the tools above, you can work your way through the colour grades of the polishing papers, starting with number 1 (the coarsest) and ending with number 6 (the finest), ensuring that you change the direction of your polishing action between grades for more even results. You will find the sanding marks will get smaller and then completely disappear.

As with sanding sheets, better results can be obtained when the paper is glued to (or even wrapped around) a small, flat piece of wood. The finish you can achieve with these is very good but if you are after a mirror finish you may wish to apply some rouge on a piece of leather, suede or similar - read more about this below.

Using Tripoli & Rouge Polishing Compounds

One of the most widely used methods for polishing is to use polishing compounds which have minuscule abrasive particles held together in a binder for easy application. These are best used at high speeds so the polish can be applied to small polishing mops, wheels & points (we sell a variety of useful shapes) and used with our Dremel Multi Tool or a similar hobby drill.

Begin with tripoli

Start with tripoli pre-polish and apply the compound to your polishing mop; start the mop spinning and then hold your polish bar against it until you can see polish on the mop. Firmly grip your piece and gently use the spinning mop all over the piece (make sure you keep the mop moving to change the direction of the polish) until it is all pre-polished. There is no need to use excessive pressure when polishing as the compound should cut through the surface on its own; if you are not seeing the results you expect, add more tripoli to the mop and try again.

Don't forget! Do not cross contaminate mops with tripoli with rouge

It is vital not to cross-contaminate your polishing mops as even a small amount of tripoli mixed with rouge can compromise the mirror shine effect. This means that it is essential to have separate mops for tripoli and rouge and also that it is important to be sure that all traces of tripoli are removed from the piece before moving on to rouge.

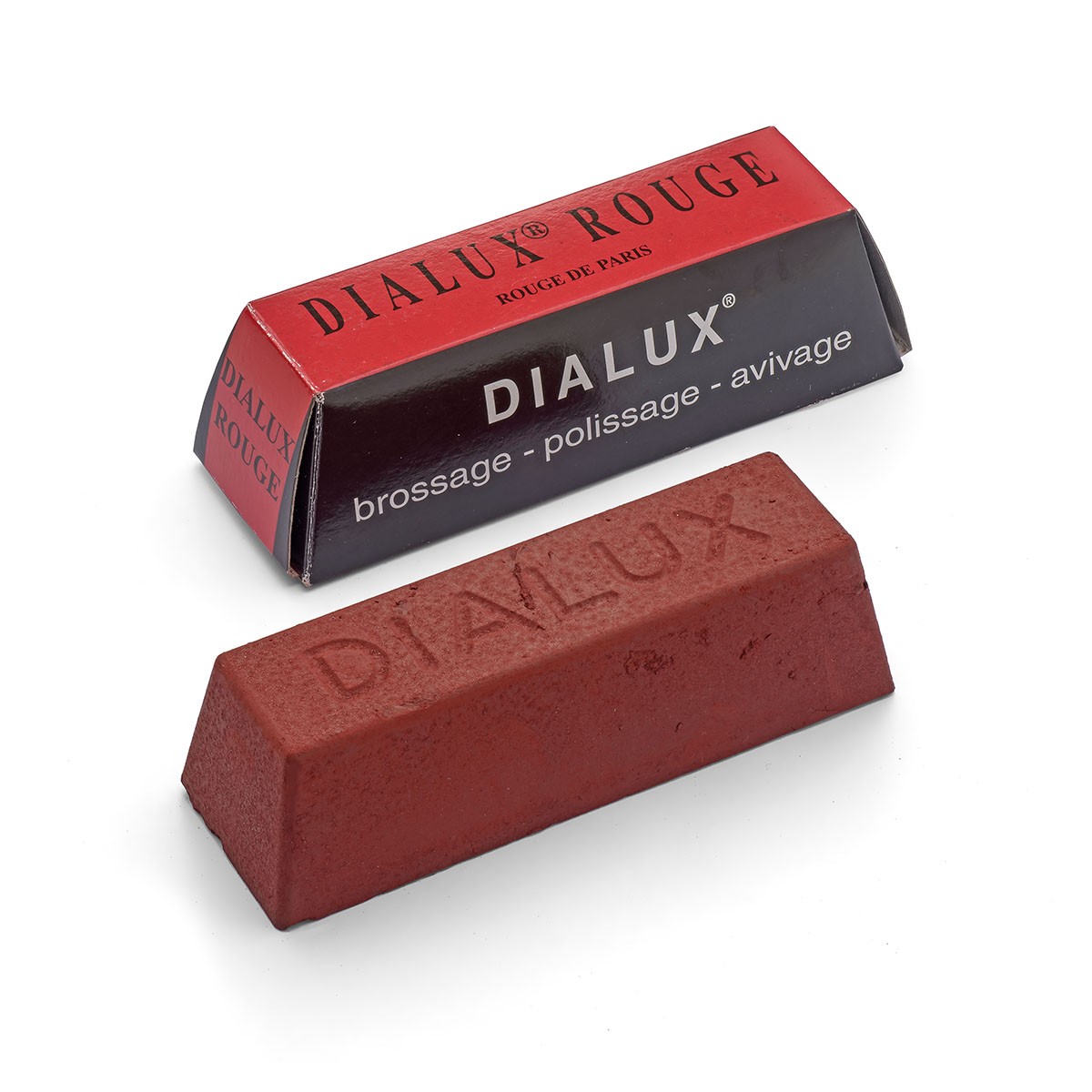

Next, apply rouge

Next, follow the same process using rouge (remembering to be careful about cross-contamination at all stages) and watch your beautiful mirror finish appear.

When using a bench polisher or bench grinder

For use with a bench polisher or a bench grinder we recommend the calico mop for applying tripoli and the swansdown mop for use with rouge. As with a hand drill, start the mop spinning and apply the polish to the moving mop. Starting with tripoli, gently press your piece against the spinning mop keeping it low down at all times to avoid it catching and being wrenched from your fingers. If this does happen the piece will be flung backwards and downwards away from you so you may find that a couple of old boxes behind the mops are useful for catching flying pieces (especially if your workshop is not the tidiest!). Use the mop all over the piece, ensuring that you keep it moving to change the direction of the polish until it is all pre-polished. Next, follow the same process using rouge (remembering to be careful about cross-contamination at all stages) and watch your beautiful mirror finish appear.

Shop calico & swansdown mops here

Using polishing compounds by hand

If you do not own a bench polisher or a pendant drill, do not despair as the polishing compounds can also be applied by hand with tough material such as leather and suede or even with string. For application with leather, suede or similar rub the polish bar against your fabric and then rub it vigorously onto your piece, making sure you change direction often to avoid marks. String can be useful for polishing in hard to reach places as the polish can be applied to the string and then this can be threaded through small gaps and pulled back and forth to polish internal gaps.

Clean up

However you decide to apply the polish, it will need to be removed afterwards as small amounts of the polish will build up in any recesses. Once you have achieved your sparkling mirror finish you will find that it will easily pick up fingerprints, greasy marks and the like so always keep a jewellery polishing cloth handy for a quick buff when you need your creations to look at their best.

Avoiding & Removing Fire stain

If dark ‘shadows’ appear on your piece during polishing, it is probably firestain (or firescale). Firestain mainly affects sterling silver due to the copper content but it can also appear on gold if the copper content is high. The very high temperatures that the metal reaches during soldering cause the impurities within the metal to be raised to the surface which can cause this subtle discolouration (large flat areas are particularly susceptible). The pickling process where items are placed in a bath of pickle solution after soldering helps to reduce this but it will still occur from time to time.

The annoying thing is that firestain inevitably shows up during the final polish (it can sometimes make polishing compound adhere to the surface of your piece) and unfortunately, if the firestain is not removed it is likely to darken with time and become even more prominent so it must be dealt with as soon as you notice it. This must be done by going back and sanding and polishing the piece again – don’t be tempted to try to use polishing compound to remove the stain as you are likely to polish away the softer silver around the harder, copper deposits which will only exaggerate the problem.

A top tip is that using argotect as a flux can help to reduce firestain occurring in the first place as it helps protect against the build-up of the impurities which cause it.

Photo from Gemiprecious Jewellery Designs shows an example of fire stain on sterling silver, however it's important to note that fire stain can be very subtle with an almost imperceptible shadow.

Stage 4: The Final Finish

Whilst a very high shine can still be achieved in the polishing stage there are certain products that can add that extra glistening touch...

Burnishing

Burnishing is technically defined as 'the plastic deformation of a surface due to sliding contact with another surface'. It is an ancient technique where hard materials such as steel are rubbed against softer metals such as silver and gold to smooth rough metal particles down leaving a shiny surface.

The burnisher has a wooden handle and a steel blade which is rubbed against the metal to polish it; oil or wax can be used to make the action even smoother. It is possible to use this technique for polishing flat areas of metal but it may be hard to create a real mirror shine this way. Softer metals such as fine silver or pieces made from metal clay are more receptive to burnishing so a shinier finish may be achieved by burnishing and these metals can even be burnished using agate stone. Burnishing is a great way of highlighting raised areas of texture by rubbing over the higher parts of a design and creating a lovely contrast to deeper, non-polished areas. This contrast can further be enhanced by creating a patina with liver of sulphur and then burnishing the raised areas, making the difference between the bright, shiny, burnished areas and the dark, oxidised areas even more dramatic.

A burnisher is an extremely useful tool to have in your workshop as it can be useful for smoothing bezel settings over gemstones and giving the top edge (which is very visible) a lasting, shiny finish. It can also be used for removing scratches caused by setting slips which may be difficult to remove without damaging your stone. Rub the burnisher sideways along the direction of the scratch (take care not to rub in the other direction as this can make the mark worse) until it is smoothed out; a drop of oil can help keep the smoothing action nice and steady which may help with this. With time and practice you will learn just the right amount of pressure required for effective burnishing.

Two types of burnisher are available, a straight style and a curved one. Both have their uses in the workshop but, if in doubt, we recommend you have the curved style as we find this is the more versatile out of the two.

Polish Multiple Pieces With A Barrelling Machine

If you are polishing multiple pieces or if you often make pieces which are hard to polish using a mop (perhaps very small pieces or pieces with internal shapes which are tricky to reach) it is worth investing in a rotary tumbler kit.

An essential tool in professional jewellery workshops (and often used by hobbyist jewellers), these clever polishing machines are often called barrel polishers or tumble polishers. They consist of a barrel shaped container which sits on top of a motor and is rotated. Steel shot (consisting of small pieces of shiny steel in various shapes) is placed inside the barrel with water and barrelling solution and then jewellery pieces to be polished are placed inside the barrel.

The machine is turned on for approximately 1-2 hours so the barrel moves the contents around and the action of the steel shot swirling round gently burnishes your jewellery pieces while you get on with something else, which is the real beauty of these machines! There are a few limitations with rotary tumblers: gem set pieces should never be tumbled with steel shot as the stones will come our looking dull, satin-finished or scratched; chains can become badly tangled and delicate protrusions can be bent during the process.

The kits we sell have everything you will need to get polishing and if you fancy a new hobby we even have a complete kit for polishing stone and glass as well as metals!

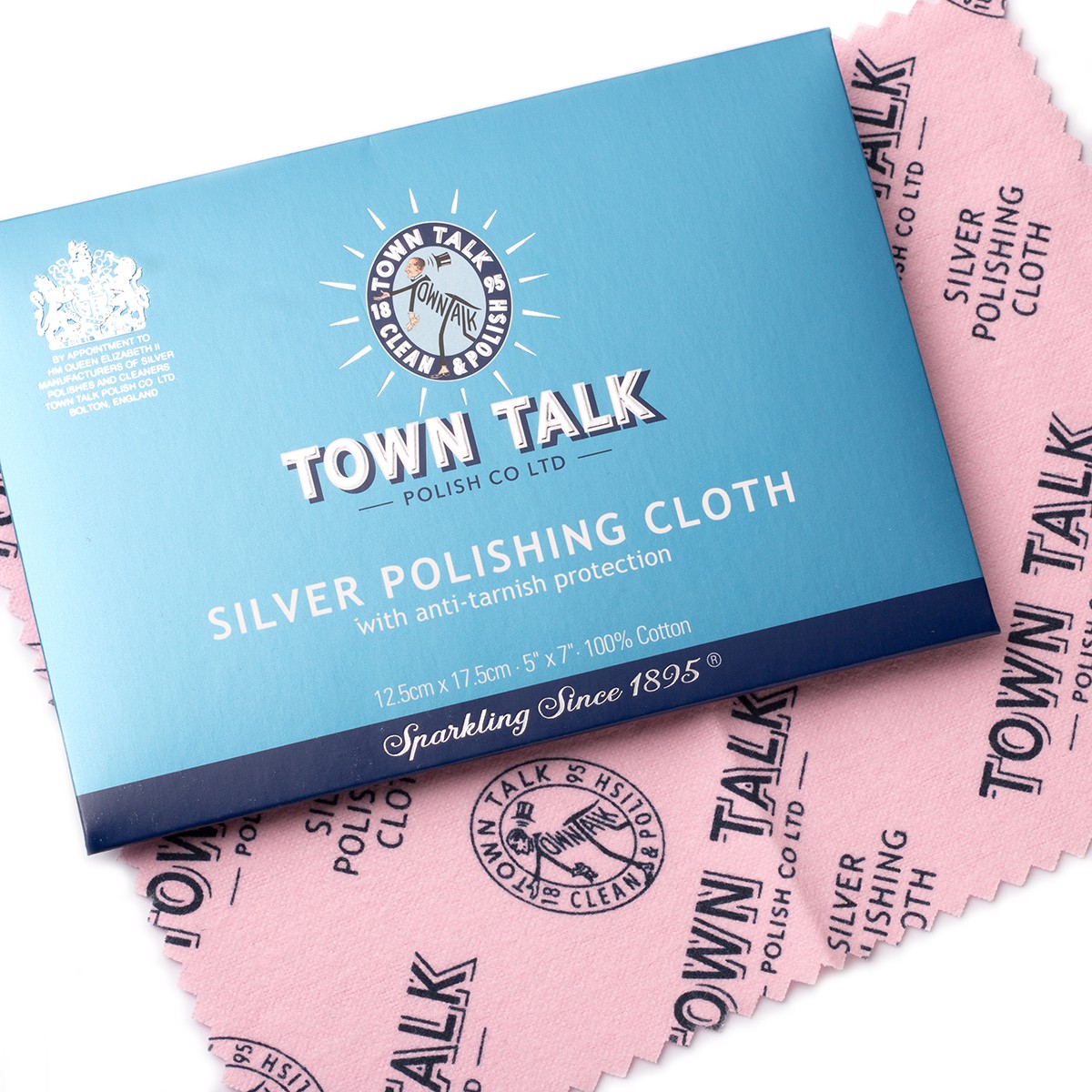

Jewellery Polishing Cloths

A must have for all jewellery makers or jewellery owners; simply buff the metal surface with the cloth and bring back the sparkle! No extra polishing compound is necessary as the cloth is impregnated using micro-abrasive technology.

Great for getting rid of tarnish and giving your jewellery a quick polish before wearing or selling to ensure it is always sparkling and looking its best.

Keep Reading...

Polishing And Finishing For Jewellers By Stephen M Goldsmith

Polishing and finishing is a highly skilled specialist craft, a professional finish will transform a piece of jewellery or silver into a work of art. This practical book is an invaluable guide to the process. Written by a leading master polisher, it explains the traditional techniques and shares the secrets of this often under-rated craft.

Read our interview with Stephen over on our Meet The Jeweller blog series

Wear Eye Protection

Anti Mist Eye Goggles

These eye protection goggles have a tough polycarbonate lens suitable for protection against medium energy impact from high speed particles and a vented body to help prevent misting. They are lightweight and have an adjustable elastic strap so are comfortable to wear and fit over prescription glasses.

Keep Your Fingers Protected

Alligator Tape

Don't forget to protect those fingers! Alligator tape is a clever self-adhering fabric tape that will protect your fingers from minor cuts, abrasions and burns during jewellery making. The tape is thin and flexible and it provides great grip when filing, sanding, polishing, buffing, grinding, assembling and stone setting.

Finger Protectors

Our finger and thumb protectors are great for wearing whilst using a polishing machine. They are soft so they will not compromise finger movement, enabling you to hold small pieces of work whilst polishing.

To view all of these products and more, visit our Sanding, Polishing and Cleaning Supplies category on our website!

Also in this section:

- Guide To Sanding & Polishing For Jewellery Making

- Hand Polishing Your Jewellery With Polishing Papers

- A Guide To Texturing Metals For Jewellery Making

- Top Tools For Making Textures On Metal

- Beginner's Guide To Chasing & Repoussé

- How To Make Easy Textured Earrings

- How To Make A Hammered Copper & Silver Heart Pendant

- How To Make A Textured Cuff Bracelet

- How To Make A Metal Leaf Decoration

- How To Use Doming Block & Punches For Jewellery Making

- How To Make Domed Metal Earrings With A Doming Block

- How To Engrave Your Drawings On Art Clay Copper

- Textured Washer Bracelet Tutorial With Guest Jeweller Laura Grey

- Barrelling Machine For Polishing Metal - Everything You Need To Know

- Tumbling Machine For Polishing Stones and Glass- Everything You Need To Know

- Polishing Jewellery Q&A With Stephen M Goldsmith

- Town Talk Products For Cleaning & Caring For Jewellery

- Creating A Resin Bird Pendant With Designer Sarah Hoare

- VIDEO: How To Create Patina With Liver Of Sulphur

- 2 Ways To Apply Liver Of Sulphur

- VIDEO: How To Use Silver Plating Solution

- How To Clean & Prevent Tarnished Jewellery

- Why You Need Anti Tarnish Paper Strips

- How To Use Midas Finish Seal Lacquer

- How To Use Renaissance Wax To Prevent Tarnished Jewellery

- VIDEO: Working With Crinkle Metal Sheet

- A Guide To Using Mokume Gane Metal For Jewellery Making

HAVE A QUESTION?

If you have any questions, feel free to get in touch with our friendly team who will be more than happy to give you advice over email or on the phone.

You can learn more and find inspiration by visiting our Jewellery Making Tutorials, Jewellery Making Kits and YouTube Channel. Don't forget to follow us on social media and tag us in your designs on Instagram & Facebook, we would love to see!