How To Work Harden Jewellery Making Wire

We share with you simple ways you can work harden metal wire for your jewellery designs. Get all the tools and supplies online with Kernowcraft!

What is work hardening?

Work hardening in jewellery making, is the process of changing the temper of the wire to make the wire stronger.

Why do I need to work harden my wire?

Metal jewellery wire comes in a range of hardness - soft, half hard and hard. When using soft wire for example, you will find that it is really easy to bend out of shape which means you need to work harden it to withstand your chosen design and ensure it doesn't lose its shape.

Can you undo work hardening?

Although it's not really necessary for wire wrapping techniques, you can undo work hardening by the process of annealing. This is heating the wire to a certain temperature which will soften it and make it malleable again.

Can you work harden too much?

Yes! Be aware that work hardening metal wire too much can make it brittle and can cause it to snap. Always keep testing your wire during the process of work hardening to ensure it isn't being worked on more than necessary. If you find that the wire is on the edge of breaking, you can anneal it to avoid this from happening.

Do I have to work harden before starting my design?

This depends on your chosen design however if you can, it's recommended to start work hardening before creating your design. Be careful if you are work hardening later on, especially if you have added gemstones as you don't want to risk damaging them.

What metal can you work harden?

You can work harden most jewellery making wire including silver, brass, copper and gold. We would recommend doing some research if you plan on using another metal before going ahead.

Shop jewellery making wire with Kernowcraft

Explore our range of jewellery making wire to suit your needs. From sterling silver, eco-friendly, 9ct gold, copper and brass. Our sterling silver and 9ct gold wire is supplied soft (fully annealed), and our copper and brass is half hard.

Our sterling silver, eco-friendly silver wire and 9ct gold wire can be cut to the size that suits you.

Watch Simple Ways To Work Harden Your Jewellery Wire

Option 1: Use Nylon Jaw Pliers

Pull & Squeeze

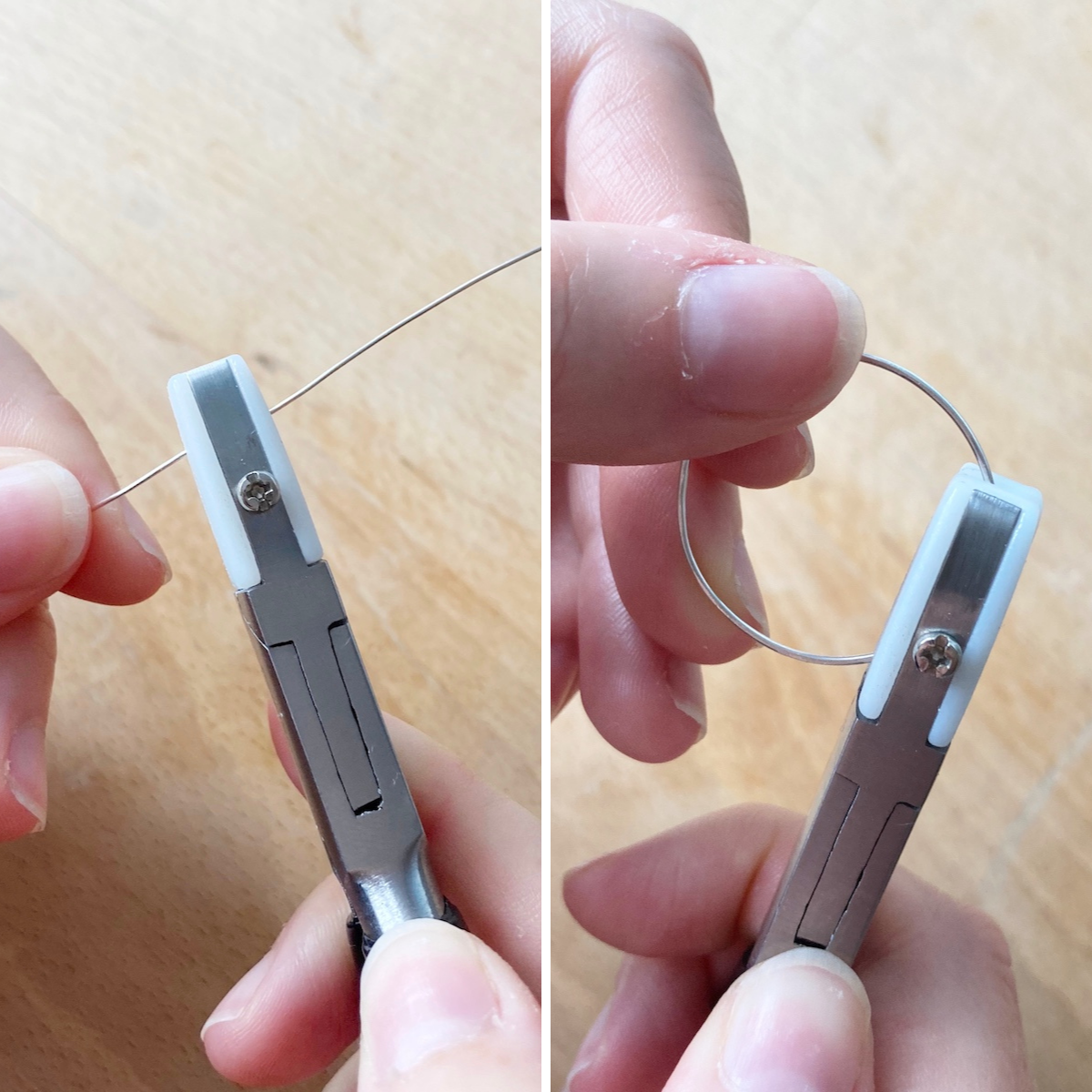

Nylon jaw pliers are an essential for all jewellers working with wire. Not only are they great as they don't mark or scratch your work, they can also be used to work harden your wire - and to straighten it too!

Simply pull the wire through the jaws multiple times until the wire feels stiff. They are also great for squeezing over finished pieces of jewellery to add that extra strength.

Shop nylon jaw pliers

These professional quality pliers by Beadsmith have double nylon jaws - great for opening and closing large jump rings or when using wire wrapping techniques. These pliers are particularly useful to straighten out wire too. They are a box jointed construction for ease of use and the nylon jaws can easily be replaced when necessary.

Option 2: Twist The Wire

Hold & Twist

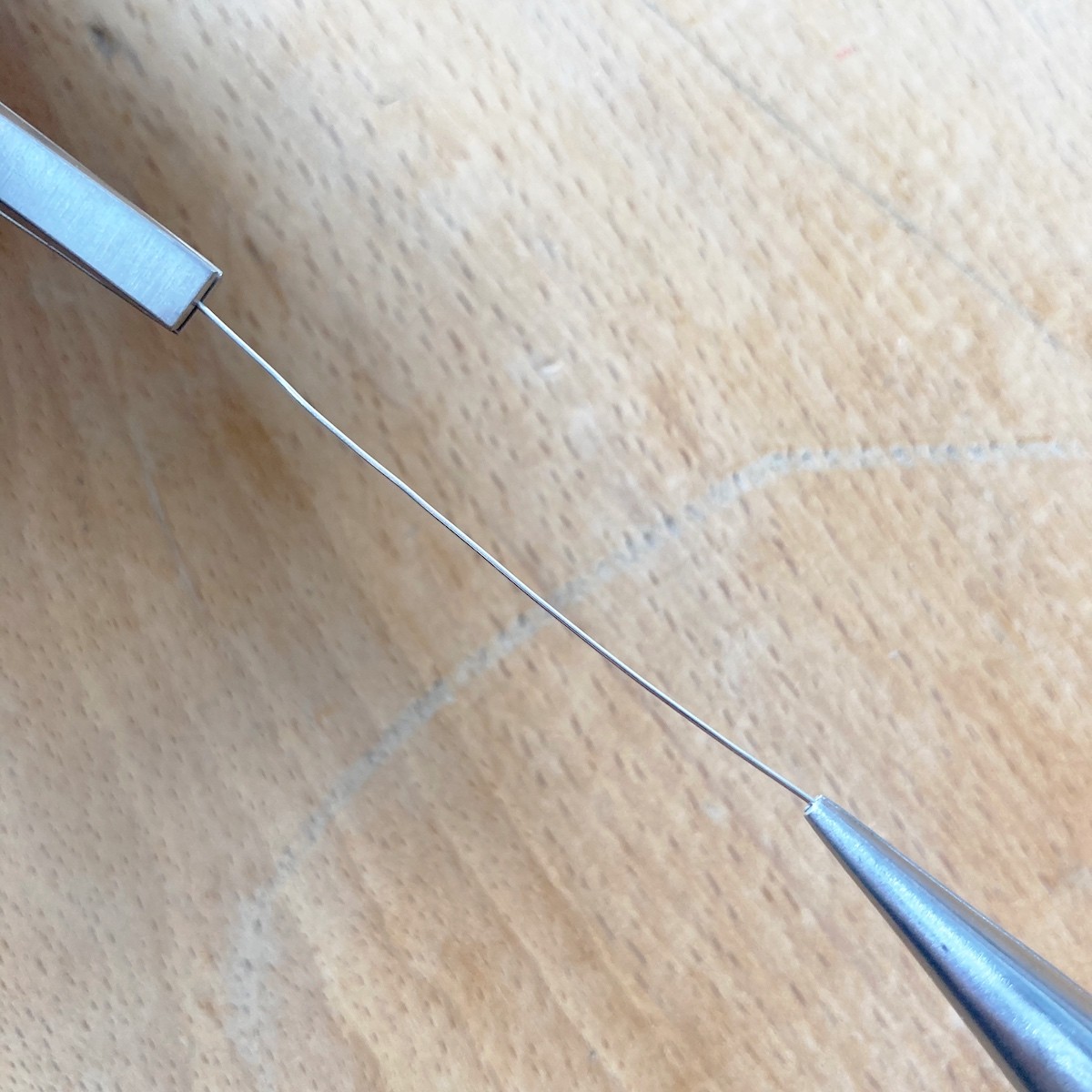

This is another simple and quick way to work harden your metal before using it. Use flat nose or snipe nose pliers to hold the wire between the tips of the pliers, hold tight and twist until it hardens. We love using this technique before creating gemstone bead bar necklaces, especially on 0.3mm wire which is quite thin and could easily lose its shape.

Shop Pliers With Kernowcraft

You will find a range of high quality jewellery making pliers and wire cutters on our website, for all your jewellery making needs.

Option 3: Tap With A Hammer

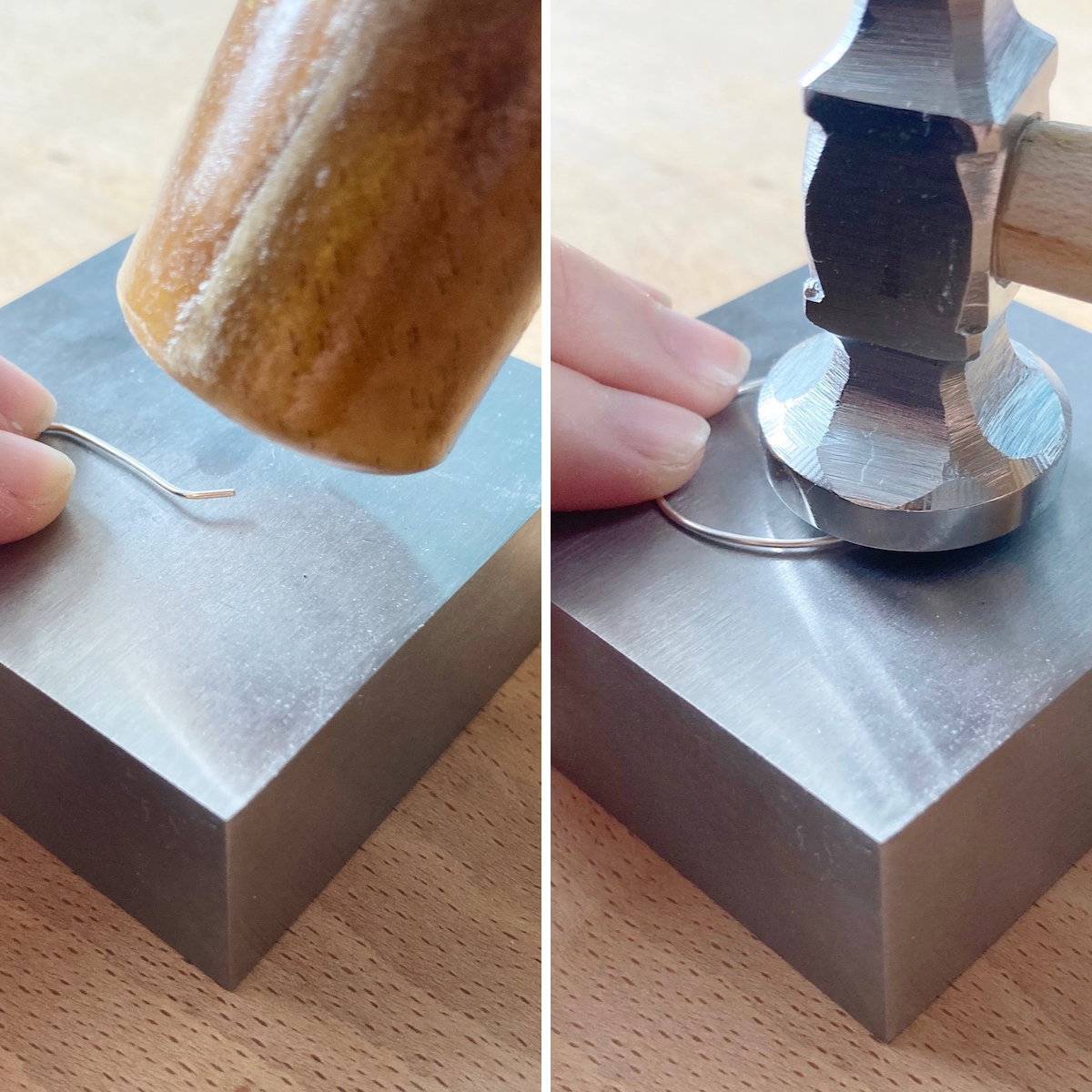

This technique is great for using on pieces like earwires and hoops to strengthen them.

All you need to do is place your piece onto the steel block and use a hammer to gently tap the piece until it hardens.

A rawhide mallet is great to use as it won't damage your work, a chasing hammer on the other hand will flatten your work slightly as well as harden it.

You can also use the rounded end of a chasing hammer to create a gorgeous hammered textured effect, which will also harden it in the process.

Steel Block

Use a steel block to hammer and form metal on - perfect for both wireworkers and metalsmiths.

Chasing Hammer

Also known as a repousse hammer - this is a great tool for forming and raising shapes from sheet metal.

Option 4: Tumble Multiple Jewellery Pieces

If you have multiple pieces of jewellery that need work hardening, you can use a barrelling machine!

It's best to work harden your jewellery before working on it, however popping them into a barrelling machine will harden the outer layer of the metal and make it stronger.

The machine works by 'tumbling' stainless steel shot around in the spinning vaned or paddled barrel which impacts on your jewellery acting like thousands of tiny hammers planishing the surface of the metal, polishing it to a high shine.

Using the barreling machine for a final polish & to gently work harden your designs. It is perfect for the polishing silver (all types including sterling silver and fine silver as well as tarnish-resistant silver), gold, copper, bronze, palladium, platinum and all metal clays.

Metalsmithing: Work Hardening & Annealing With Kim

This video is from the 12 Months Of Metal series with Kim Thomson, that you can find over on our blog! See all tutorials here

Also in this section:

- How To Make A Wire Wrapped Nest Necklace

- Tools For Making Jewellery Using Wire

- Your Guide On Choosing Wire For Jewellery Making

- Compare Jewellery Designs Using Different Sized Wire

- Wire Gauge Coversions

- How To Work Harden Jewellery Making Wire

- How To Use Nylon Jaw Pliers For Jewellery Making

- How To Use A Thing-A-Ma Jig For Jewellery Making

- How to Wire Wrap a Bead With a Headpin

- How To Wire Wrap A Bead

- How To Make A Wire Wrapped Bead Chain

- How To Wire Wrap A Briolette

- Wire Wrapped Cluster Briolette Earring Tutorial

- How To Make Wire Wrapped Bead Necklace With Handmade Clasp

- How To Wire Wrap A Rough Crystal

- How To Make Valentine's Day Earrings: Wonky Wire Hearts

- How To Make A Wire Wrapped Crystal Necklace

- 6 Wire Wrapped Ring Projects & Essential Tools

- How To Make A Wire Wrapped Bead Ring

- How To Make An Anxiety Ring

- How To Make A Wire Wrapped Gemstone Ring

- How To Make A Wire Wrapped Cabochon Pendant

- How To Make A Tree Of Life Pendant

- How To Wire Wrap A Gemstone Donut

- How To Make Christmas Tree Earrings

- Simple Sterling Silver Wire Scroll Earrings

- Soldered Circle Hoop Earrings With Beads Tutorial

- How To Make Wire Hoop Earrings & Customise Them

- Metal Charm Hoop Earring Tutorial

- How To Make A Wire Word Necklace

- 4 Wire Wrapped Gemstone Tube Bead Projects

- Festival Inspired Crystal Necklace Tutorial

HAVE A QUESTION?

If you have any questions, feel free to get in touch with our friendly team who will be more than happy to give you advice over email or on the phone.

You can learn more and find inspiration by visiting our Jewellery Making Tutorials, Jewellery Making Kits and YouTube Channel. Don't forget to follow us on social media and tag us in your designs on Instagram & Facebook, we would love to see!